Home > Products > Prototype and CNC machining parts > plastic injection molding parts for medical devices rapid prototype maker.

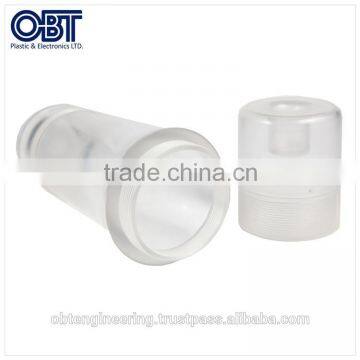

plastic injection molding parts for medical devices rapid prototype maker.

- Yantian

- T/T Credit Card

You May Like

-

cheap rapid prototyping for Medical equipment china plastic prototype maker

-

Cheap rapid Plastic Prototyping

-

CNC machining parts silicon parts injection molding parts

-

CNC machining Silicon parts molding maker injection molding parts

-

Latest Google cardboard VR BOX 2.0 Version VR Virtual Reality Glasses rift 3d Games Movie for 3.5" - 6.0"Smartphone

-

2016 VR BOX 2.0 Version 2 VR Virtual Reality Glasses + Smart Bluetooth Wireless Mouse / Remote Control Gamepad

Product Description

plastic injection molding parts for medical devices rapid prototype maker.

Feature:

Prototypes are important in the development process of plastic injection molded components. Saving time and money by helping detect design flaws and other issues in the design phase. With over 12 years of experience in providing injection molding prototypes, OBT will work with you to develop injection molding prototypes that will work successfully for your project.

Plastic injection molding prototypes can be produced quickly to meet the demand of tight development time lines. Prototypes can also be painted and decorated to appear much like the final product for marketing use prior to availability of production parts.

Why Plastic Molding Prototyping?

The use of injection molding prototypes can facilitate efficient and cost effective evaluation of a part’s form, fit and function and can also be painted and decorated to appear much like the final product for marketing use prior to availability of production parts.

OBT employs a full range of technologies for plastic injection molding prototyping, from traditional CNC machining to a full range of additive. manufacturing rapid prototyping technologies, including:

.Traditional CNC Machining

.3D printing

A rapid prototyping additive manufacturing process laying down successive layers of material directly from a CAD model that can create almost any geometry, including undercuts, overhands and internal volumes. 3D Printing additive manufacturing also offers relatively inexpensive and fast production for a small number of parts.

.Selective Laser Sintering (SLS)

A rapid prototyping additive manufacturing process using a laser to sinter powder based materials together, layer-by-layer. Forming a durable solid prototype model ideal for functional parts in a variety of applications.

Selective laser sintering (SLS) also enables production of injection molding prototypes with snap fits and living hinges.

.Stereo lithography(SLA)

A rapid prototyping additive manufacturing process employing a UV laser and vat of liquid UV-curable photopolymer resin to produce prototypes quickly. One layer at a time. SLA injection molding prototyping is ideal for check part sizing, fit and function and for use as finished part looking marketing prototypes.

.Fused Deposition Modeling (FDM)

A solid-based rapid prototyping additive manufacturing process that extrudes material layer-by –layer to build the prototype. Fused Deposition Modeling(FDM) is ideal for producing conceptual and engineering models and functional testing plastic injection molding prototypes.

Prototype Molds/Pre-Production Injection Molds

A plastic injection molding prototype mold can be very important in the development of a new product. Offering a fast. Low cost tooling solution for producing parts for fit & function testing. Prototype molds also offer the advantages of testing the molding process and molding with the production material. So many process or material based design flaws are discovered early on. Saving time and money in development.

Prototype molds can be use for low volume plastic injection molding production.

OBT injection molding prototype mold capabilities include:

.Quick lead time tooling/rapid prototypes

.One cavity pulls up in a multi-cavity base

.Master Unit Die inserts

.Single cavity to multi cavity

.Short run molds

.Simple or complex geometrics

.Aluminum or hard tool steel

Performances of plastic materials:

| material | properites | applications |

| ABS | 1.chemical stability,oil resistance,good rigidity and hardness 2.non-toxic,water-proof,low water absorption 3.excellent low temperature impact resistance,abrasion esistance,chemical resistance 4.low heat distortion temperature 5.great weather resistant | Automotive industry, electrical instrumentation industry, home electronics appliances |

| PC | 1. non-toxic,odorless,tasteless, excellent oil resistance 2.good creep resistance,good dimensional stability 3.good high-frequency insulation | high transparency and high impact areas, automotice industry, electrical and electronic industry, construction areas |

| PP | 1.non-toxic,odorless,tasteless,translucent or transparent 2.strength and hardness,high flexibility 3.heat resistance,chemical stability 4.high-frequency insulation 5.weather resistance | fcilm products, injection molding products, extrusion produts |

| POM | 1.high performance and easy to color 2.high strength and hardness 3.excellent tensile strength,bend strength,creep property and fatigue resistance,impact resistance 4.low friction,good dimension stability,perfect surface polish,low absorption,good electrical insulating 5.good flexibility | machine components, auto industry, electronical industry, construction and agriculture area |

| PEEK | 1.high temperature resistance 2.good toughness and rigidity 3.self-lubricating,abrasive-resistant 4.chemical and corrosion resistance 5.flame-retardant 6.radiation-resistant,fatigue resistance | aerospace field, electronic area, medical equipments, oil industry, mechanical industry, automotive industry |

About Us :

Shipping :

Why Choose Us?

FAQ:

1. Wha is your MOQ?

Our MOQ is 1000Pcs, of course samll orders are welcome as well.

2. How about the delivery time and the shipping time?

10-30working days,depending on quantity, Regarding shipping time about 3-5days Via DHL

3.How do you guarantee the correct size,material and hardness when i receive the goods?

Before shipping, we will send you our specification report.

4.What is your payment Methods

T/T&Western Union, generally, 30% deposit, the balance before shipment

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Ms Tammy Tian

Tel:+86 755 26810950

Mob: +86 13570889415

WeChat:tammy2641

Skype:Sales1OBT

Contact Us

- OBT PLASTIC & ELECTRONICS USA LLC

- Contact nameamber Zhang Chat Now

- Phone001-408-7186290

- Address955 Benecia Ave,

Product Categories

| Dia casting and punch parts | electronic parts | IMD/IML parts | New Products |

| plastic products | Prototype and CNC machining parts | silicon product |

New Products

-

factory supply vr box 2.0,3d headset,3d virtual world

-

2016 Virtual Reality Glasses Vr Box 2.0 3d Glasses VR Headset For Google Cardboard Glasses For 4.7-6.0

-

factory price VR 2.0 Virtual reality vr phone use 3d glasses with headband vr box

-

2016 Hotest sales !! VR BOX 2.0 Google Cardboard Version Virtual Reality 3D Glasses VR Headset

-

High quality VR BOX 2 Virtual Reality vr 3d glasses with bluetooth

-

Die Casting Mold Part 04

-

Die Casting Mold Part 03

-

Die Casting Mold Part 10

-

Die Casting Mold Part 05

-

PCB-PCBA and Micro SMT Assembly 04

-

PCB-PCBA and Micro SMT Assembly 05

-

PCB-PCBA and Micro SMT Assembly 06

Popular Searches

- plastic mould

- Pc Abs

- Pp Pvc Hdpe Abs

- 3d design

- document

- Agricultural Plastic Products

- plastic injection

- injection moulding

- injection mold

- Plastic Injection Part

- Appliance Part

- injection mould

- extrusion die

- computer plastic mould

- home automation

- Plastic Injection Mould

- Mould Design

- rubber mold

- Automotive Plastic Products

- Molded Product

- Plastic Injection Molding Product

- Injection Moulding Product

- Moulded Product

- Injection Mould Bumper

- Injection Molding

- Household Products Part

- cycle component

- Mould Maker

- rubber flap

- bumper mold

Recommended Products

- epoxy resin cast mould transformer insulator manufacture APG process chinese manufacture

- Epoxy Resin Injection APG Moulding die casting mold

- Multi Cavity Custom plastic injection mold for Switch socket plug

- PET Multi Cavity Custom plastic injection mold

- Custom Overmolding/2k plastic Injection mold Two-Shot Plastic Mold

- Custom Plastic Mold for TV Backplate Cover White Goods

- Custom Plastic Injection Mold for Sweeper Housing

- Custom Plastic Injection Mold for Router with 3C

- Custom Plastic Mold for Hair Dryer

- Custom Plastic Household Mold for Coffee Pot Handles

- Custom Plastic Injection Mold for 3D Printer Housing-Injection Molding Service

- Custom PVC Plastic Mold for Threaded Pipe Fittings Multi Cavity Injection Molding

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Plastic Mould

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

amber Zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

amber Zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile